So Sorry, this offer has expired! Check out our other exciting deals.

PAY DAY!!

Get 10% Disc on all product *tnc apply

50 Years Legacy

We work from Bali, otherwise called as the 'Island of Gods' where we try to balance with serene lifestyle of Balinese ethos. We are respectful to the spirit of our ancestors. We nurture a living craft that is a source of livelihood for a few hundred households. We are a fashion brand that has been mindful since its inception. We believed and make long-lasting products. We are looking for creative collabs. Join this journey with us.

Uluwatulace x Bjo Furface

Uluwatulace x Sunaka Jewelry

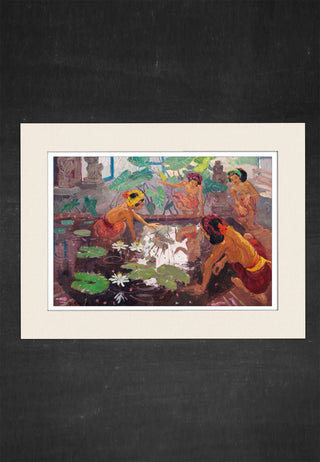

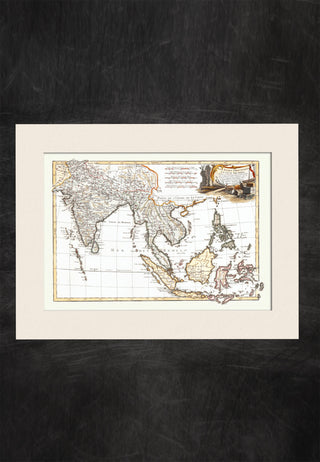

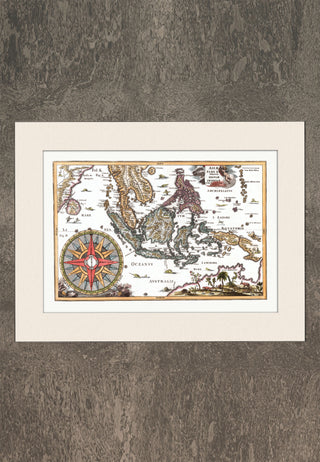

Uluwatulace x Old East Indies

"I have received the dress. It is so beautiful and the material is very good.Thank you. I like it very much."– Amanda Theo Singapore,

"I wanted to let you know that I received Nerva dress and I could not be happier! It is absolutely gorgeous and i am so exited and honored to be wearing it!"- Serena Buscarello Boston, USA

"Let's open a store in South Africa and make me your distributor. They'll love your stuff.– Naushina South Africa,

"This top (kebaya) I have it also almost twenty years now. They are still so lovely. Also have it in white. Will invest in similar ones."– Ivone Eveline Germany,

"Before wearing I went to their factory and learnt how everything is made. Such a long and beautiful process...Its always such an honor to wear the designs."– Tiana Schaper Perth, Australia

Такая красота вашими золотыми руками. ношу с удовольствием ваше платье. Сотрудники магазина нам уделили внимание и помогли подобрать подходящий вариант и по цене и по размеру..." | Such beauty with your golden hands. I enjoy wearing your dress. The store employees paid attention to us and helped us choose the right option for both price and size.– Victoria , Russia

"I love it. (Shanghai Dress)"– Sekar Ayu Dewanti Tangerang, Indonesia

I bought Uluwatu handmade Balinese since 2012 up till now. Ranging from kebaya white black for nearly every style that suits me. Also long dress, long skirts white n black, pants n many others. Usually the conservative styles. Where do I wear it? I wore it during my presentations in Bangkok, Chiang Mai, or during my interview with a Dutch journalist on behalf of my father. He is one of those National Heroes of Indonesia at the Indonesian Museum of Proclamation. I combine a white Uluwatu lace 'kebaya', black Uluwatu pants and a woven goldthread silk 'songket' shawl from Minangkabau. Voila, Indonesia.– Voila , Indonesia

WHERE PERFECTION IS A HABIT. EVERY YARN MATCHES TO HAPPY SALMA'S EXPECTATIONS.

Credit : Oppo Indonesia / Youtube

WHERE PERFECTION IS A HABIT. EVERY YARN MATCHES TO HAPPY SALMA'S EXPECTATIONS.

Credit : Oppo Indonesia / Youtube

love of lace

We tell tales of lace. Bali, our land and culture inspires these stories. If you have a story to tell, we shall publish it here. Give us a shout-out : info@uluwatu.co.id

Where Sophistication And Simplicity Exist Seamlessly

The Yak spoke with Ajit Khatai, ceo of Uluwatu handmade Balinese lace – the 50-year-old true Bali legacy fashion brand – about life in Bali, the journey...

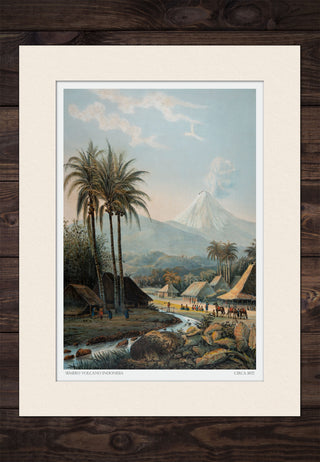

TRAVELLING TO A TROPICAL PARADISE

The tropical islands offer an unforgettable holiday opportunity with the spectacular atmosphere and where you can see every shade of blue. Here are the...

THE STORY OF WHITE

I have been staring at a blank page. It is pure white, flawless and beautiful, but also slightly terrifying because I have...

SECRET TO A CHIC & TIMELESS WARDROBE

It is true that trendy clothes can make you look different at every moment, but classic clothing can make you look downright graceful.

HOW TO KEEP WHITES TIMELESS, ORGANICALLY

We all love shining bright white, soft, and freshly scented clothes but do we really have to harm the environment while doing laundry? Here...

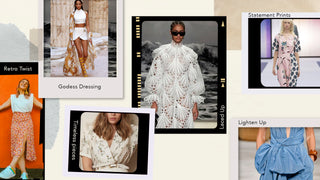

Resort wear Trends 2022

We've seen the first glimpses of what we'll be wearing in 2022, and we can hardly contain our excitement. With the world...